Several months ago,car-auto-repair.com show guide on maintenance about every 500 hours and every 1000 hours for Kubota V3800 engine.So here another post focus on Kubota V3800 engine every 1500 hours maintenance.

Related Contents:

Takeuchi Excavator Workshop EPC+Service Manual 2018 PDF Files

2022 Kubota Takeuchi Diagmaster v22.08.01 v4.1.2 Software Free Download

Kubota EPC Spare Parts Catalogue 2021.06 Download

Procedures:

Check of Injector Tip

1.Remove the injector.

2.Make sure that there are no carbon deposits on the injector nozzle hole.

3.If there are carbon deposits on the nozzle hole, remove the deposits so the hole is not obstructed.

IMPORTANT

Do not clean the nozzle hole with a wire brush or similar tool because it will damage the hole.

- Do not disassemble the injector.

- Do not remove the injector QR code tag.

- Do not damage the injector QR code tag.

- Do not lose the ball of the rocker arm bracket.

- Do not get the injectors out of order. If the injectors get out of order, it is necessary to perform injector correction (writing the indicator ID codes to the ECU).

- Store the injectors so they do not get any dust in them.

NOTE

- Replace the injectors’ gaskets with new ones.

- When installing injector clamps, check and make sure the ball is in the rocker arm bracket.

- When attaching the overflow pipe to the injector, replace the gasket with a new one.

- Tighten the injector clamp nuts securely to their specified torques.

- After installing the overflow pipe, in order the fuel leakage,add pressure by air from the fuel pipe joint, and check the fuel leakage of overflow pipe and gasket.

- In case there is fuel leakage, replace the gasket, then check the fuel leakage again.

- If you replace the injectors, it is necessary to perform injector correction (writing the injector ID codes to the ECU).

Check of EGR Cooler

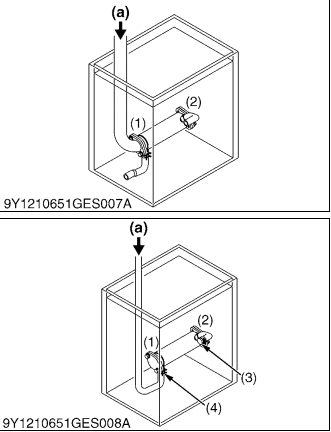

(Exhaust gas passage)

1.Block the EGR cooler exhaust gas outlet (2).

2.Attach an air hose to the EGR cooler exhaust gas inlet (1) and then submerge it in a water tank.

3.Check that the coolant passage is full of water.

4.Apply the specified amount of air pressure (a) (290 kPa,3.0 kgf/cm2, 43 psi) to the air hose side, and check that there are no air leaks in any of the EGR cooler parts.

5. If there are air leaks, replace the EGR cooler.

(Coolant passage)

1.Block the EGR cooler exhaust gas inlet (1), EGR cooler exhaust gas outlet (2), and the coolant outlet (3).

2.Attach an air hose to the EGR cooler coolant inlet (4), and then submerge it in a water tank.

3.Apply the specified amount of air pressure (a) (250 kPa,2.5 kgf/cm2, 36 psi) to the air hose side, and check that there are no air leaks in any of the EGR cooler parts.

4.If there are air leaks, replace the EGR cooler.

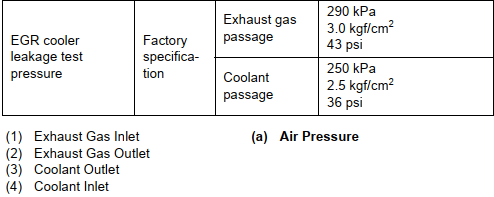

Replacement of Oil Separator Element

CAUTION

–Be sure to stop the engine before replacement the oil separator element.

1.Remove the cover (2).

2.Remove the oil separator element (4) and O-ring (3).

3.Replace the oil separator element and O-ring with a new one.

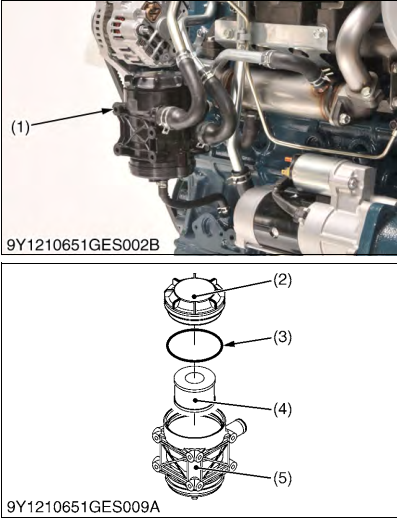

(1) Oil Separator (2) Cover (3) O-ring (4) Element (5) Body

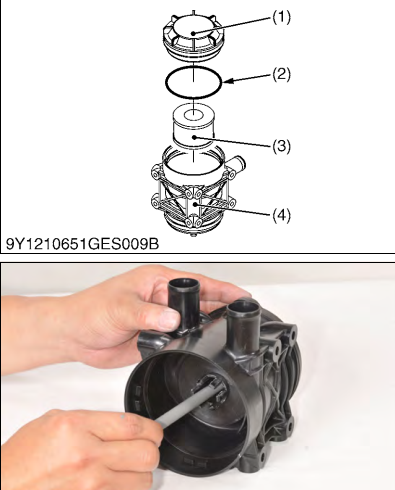

Check of PCV (Positive Crankcase Ventilation) Valve

1.Remove the cover (1) and element (3).

2.Press on the PCV valve and check that it moves smoothly.

3.If it does not move smoothly, replace the oil separator.

(1) Cover (2) O-ring (3) Element (4) Body

More repair topics about Kubota,pelase refer to Kubota Trouble Repair