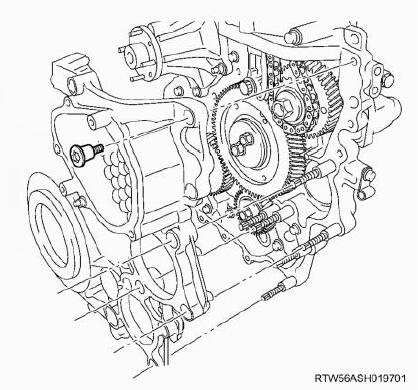

Here is a step-by-step guide on how to remove ad install timing gear train for ISUZU 4JJ1 engine Euro 4 N series truck.More about ISUZU truck cases,please refer to::ISUZU Trouble Repair.

Related Contents:

ISUZU US-IDSS II 2024 2019 Diagnostic Software Free Download

ISUZU Worldwide EPC 2018.03 Snap-on EPC Installation Service

Procedures:

1.Drain the coolant.

2.Disconnect the radiator upper hose.

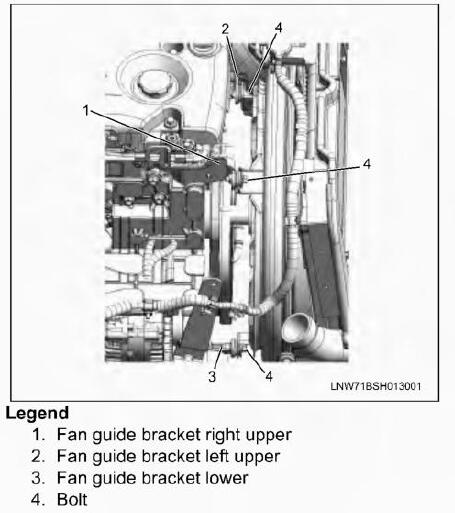

3.Remove the fan guide bracket.

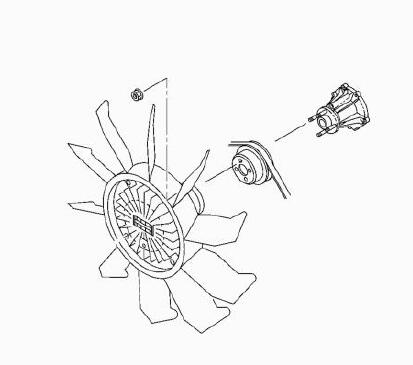

4.Remove the cooling fan and fan pulley.

5.Remove the A/C compressor drive belt and the fan drive belt.

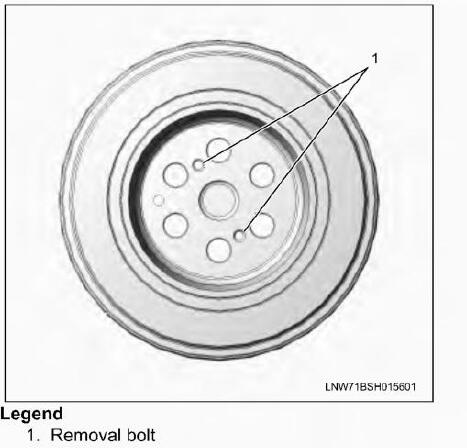

6.Remove the crank pulley.

NOTE:Do not reuse the bolt and washer of the crank pulley.

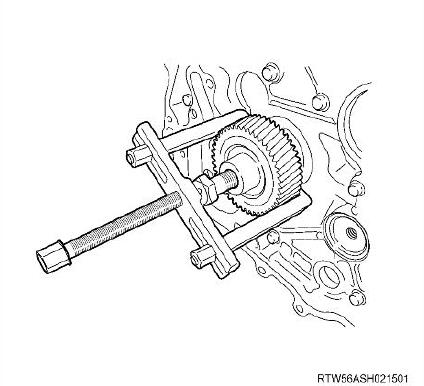

When the pulley is stuck, remove it using the removal bolt holes on the crankshaft pulley.

NOTE: Use a removal bolt of diameter 5 mm, pitch 0.8 and stem length 20 mm or longer for removal.

CAUTION: Forcibly removing the pulley without using a removal bolt may damage the oil seal, resulting in an oil leak.

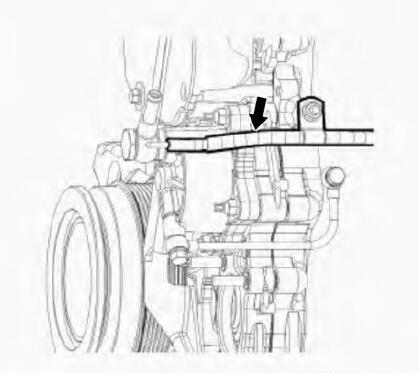

7.Remove the power steering pump at the engine side with the hose attached.

Fasten the power steering pump with hose attached to any suitable position with a wire.

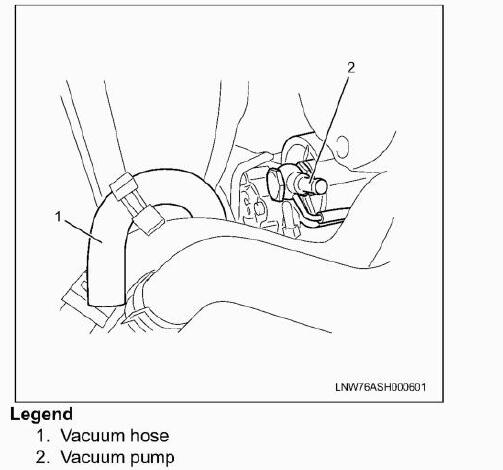

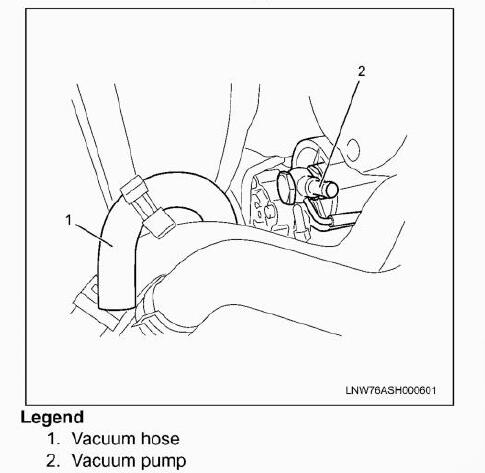

8.Remove the vacuum hose(1).

9.Remove the vacuum hose.

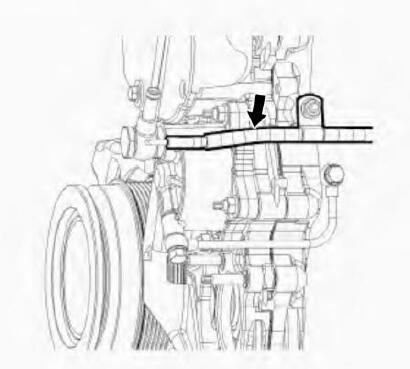

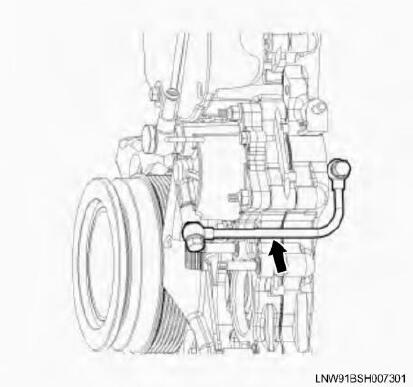

10.Remove the oil feed pipe

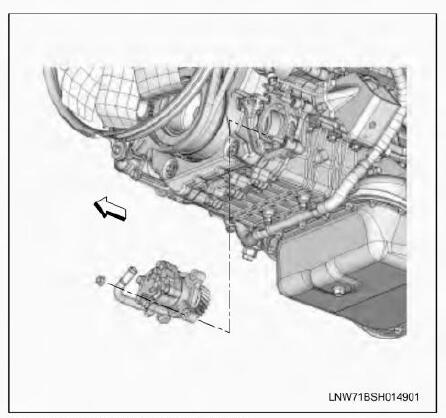

11.Remove the vaccum pump

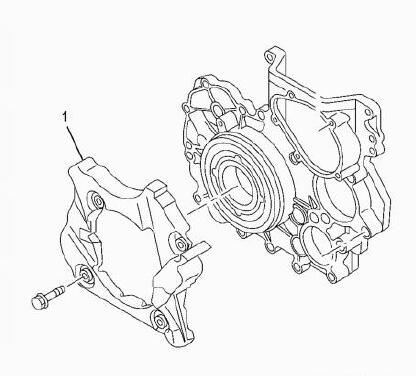

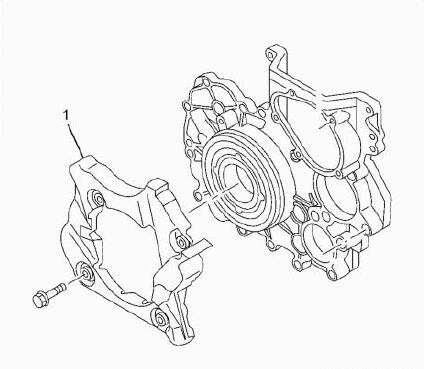

12.Remove the cover (1) of the gear case cover

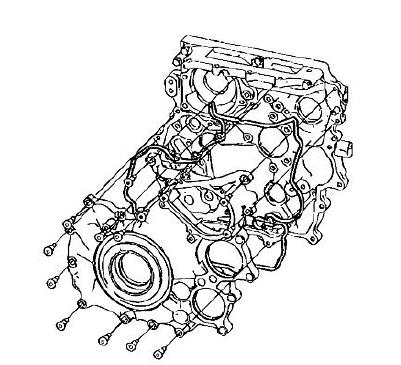

13.Remove the gear case cover

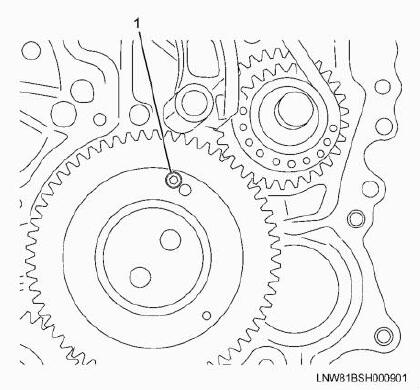

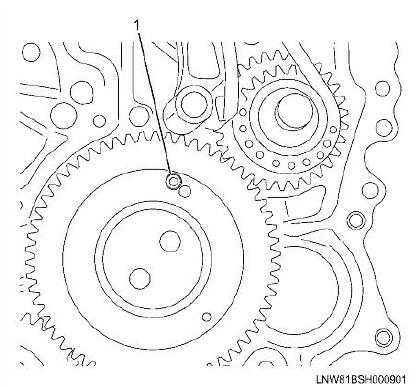

14.Install an M6 bolt(1) to the idle gear A, and align the position of the sub gear to fix it.

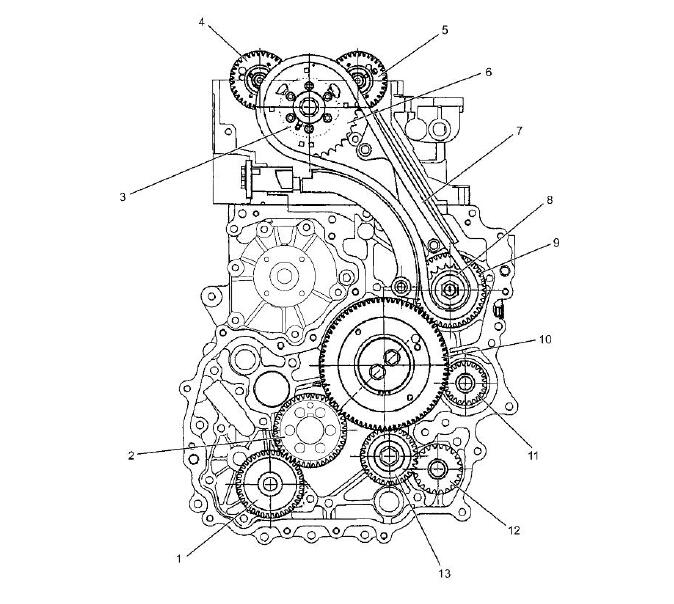

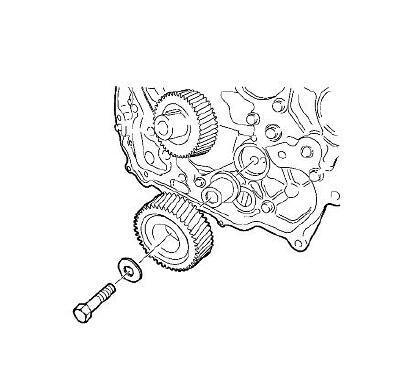

15.Remove the crankshaft gear.

16.Remove the idle gear A, idle gear A flange, and idle gear A shaft.

17.Remove the idle gear C and idle gear C shaft.

Inspection

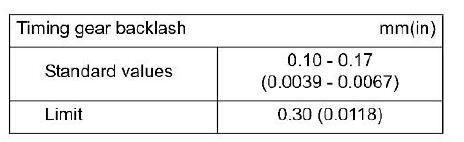

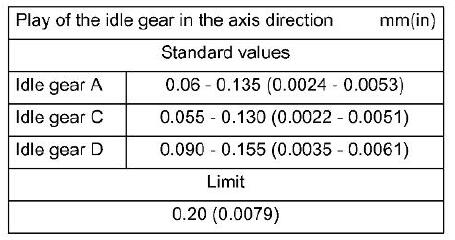

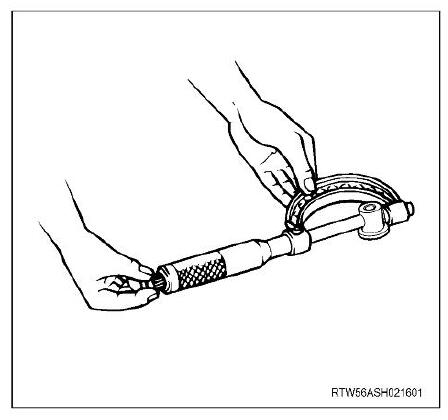

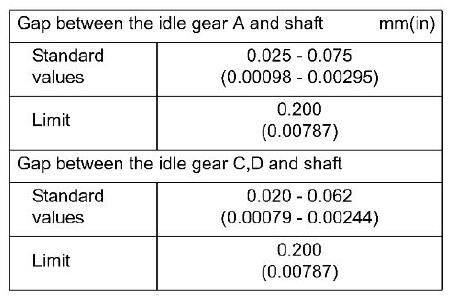

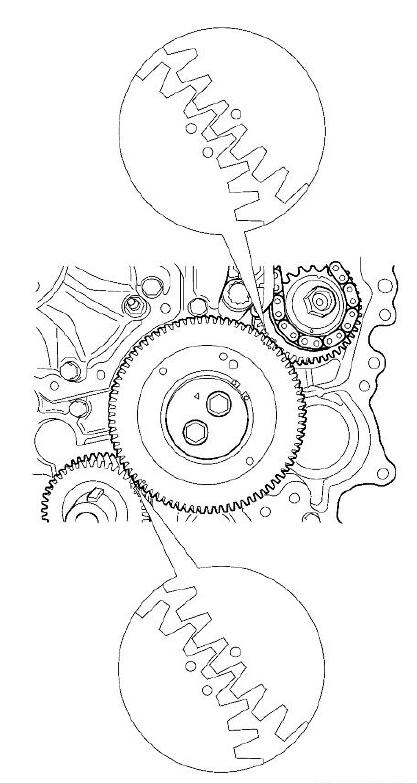

1.Measurement of idle gear backlash

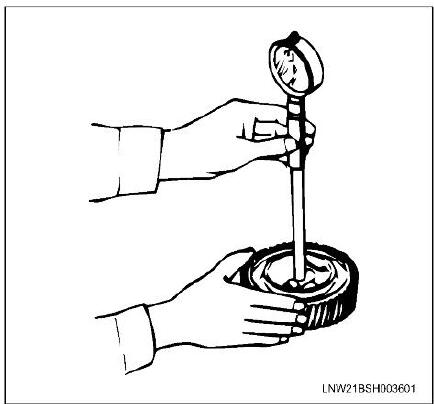

Touch the dial gauge to the idle gear tooth to be measured, and gently move the gear left and right to read the inconsistency on the dial gauge.(always fasten the other gear.)

Replace the idle gear if the measured value exceeds the limit.

Measure idle gear backlash before removing the idle gear A.

2.Measurement of play of the idle gear in the axis direction

Insert a thickness gauge into the gap between the idle gear and thrust collar to measure the gap.

3.Replace the idle gear or thrust collar if the measured value exceeds the limit.

4.Gap between the idle gear and the idle gear shaft

Measure the inner diameter of the idle gear bushing to calculate the gap between the idle gear and the idle gear shaft.

Replace the idle gear or shaft if the measured value exceeds the limit.

Installation

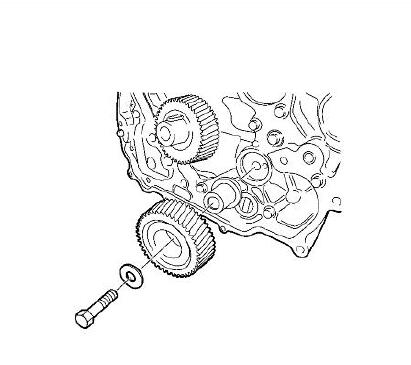

1.Install the idle gear C.

Apply engine oil to the gear assembly sections of the idle gear shaft.

Apply oil to the threaded portion of the bolt and seat surface, and temporarily tighten it.

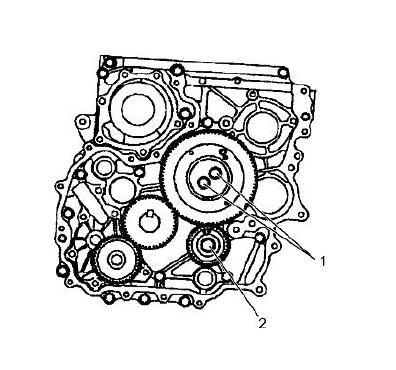

2.Install the idle gear A.

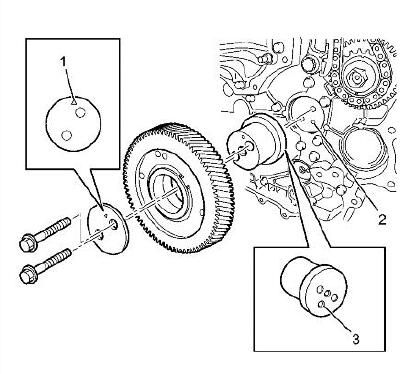

Aligning the cylinder block side oil hole(2) and the idle gear A shaft oil hole(3) to install.

Install the flange with the front mark(1) facing you.

Install the idle gear with the alignment mark aligned.

Apply engine oil to the gear tooth surface of the idle gear.

Apply engine oil to the threaded portion of the bolt and seat surface, and temporarily tighten it.

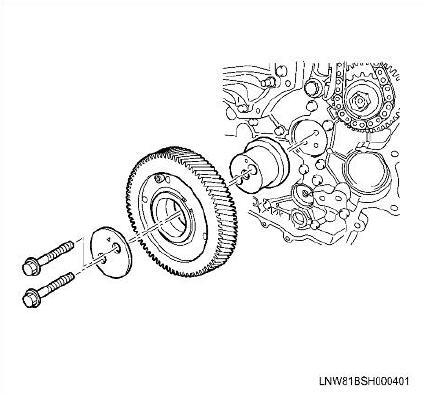

3.Install the crankshaft gear.

Align the alignment marks with the idle gear to install it.

4.Tighten the idle gear A(1) and idle gear C(2) at the specified torque.

Tightening torque:

Idle gear A32 N.m(3.3kg-m/24 lb. ft) Idle gear C 59N’m(6.0 kgm/43 lb-ft)

5.Remove the M6 sub gear fixing bolt(1) from the idle gear A.

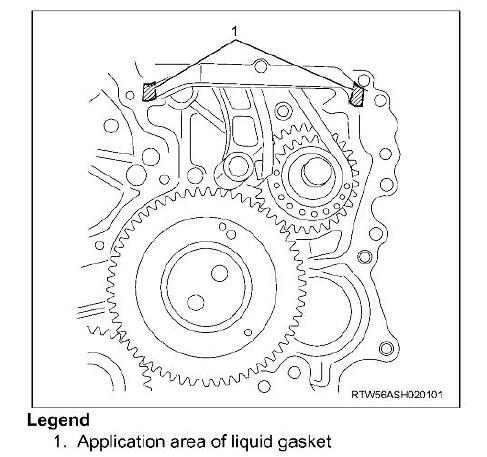

6.Install the gear case cover.

Apply liquid gasket(TB-1207B).

After applying the liquid gasket, install the cover within five minutes.

Install the gasket to the gear case cover.

Tighten the bolt at the specified torque.

Tightening torque:8 N:m(0.8 kgm/69 lbin)

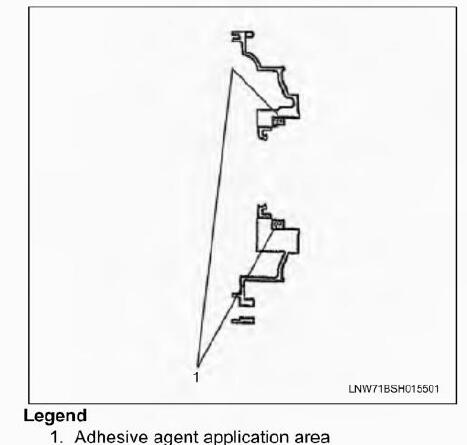

7.Install the space rubber.

If the space rubber has been removed, install the new one.

Apply the adhesive agent(EC775, TB1782, or TB1783 manufactured by 3M) to install it.

8.Install the cover(1) of the gear case cover.

Tightening torque:10 N-m(1.0 kg-m/87 lbin)

9.Install the vacuum pump and tighten them at the specified torque.

Tightening torque:25 N-m(2.5kg-m/18 Ib. ft)

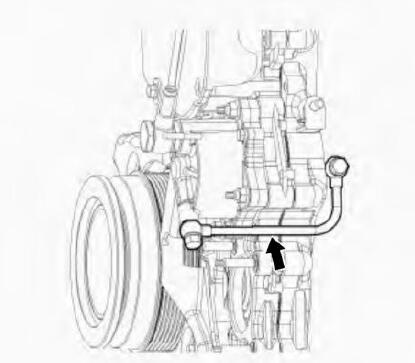

10.Install the oil feed pipe.

Tightening torque:12 N-m(1.2kg-m/104 lbin)

11.Install the vacuum hose.

1.2Install the vacuum hose(1).

13.Install the power steering pump and tighten it at the specified torque.

Tightening torque:

25N-m(2.5 kg m/18 Ibft)

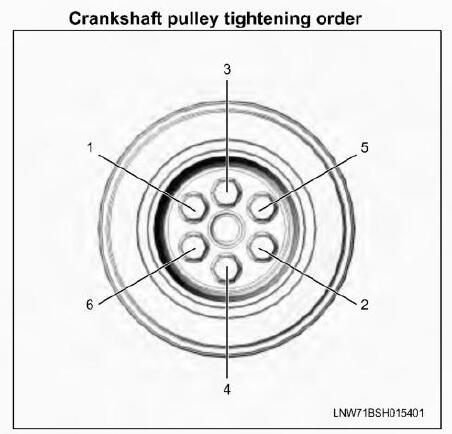

14.Install the crankshaft pulley.

a.Install the crankshaft pulley.

b.Apply engine oil to the bolt seat surface and threaded portion.

c.Install the bolt and washer.

d.Tighten to 30 N(3.1 kg-m/22 lb-ft) in the order of numbers shown in the illustration.

e.Tighten further for 180?in the order of numbers shown in the illustration.

f.Again, tighten for 60?in the order of numbers shown in the illustration.

Tightening torque: First time 30 N-m(3.1kg-m/22 lb-ft)

Second time 180

Third time60

Special Tool Angle gauge:5-8840-0266-0

NOTE: The total rotational angle of second time and third time should be 240to 270.

NOTE: Do not reuse the bolt and washer of the crankshaft pulley.

15.Install the A/C compressor drive belt and the drive belt.

16.Install the cooling fan assembly.

Tighten the fan clutch to the fan pulley at the specified torque.

Tightening torque:8 Nm(0.8 kg-m/69 lb-in)

17.Install the fan guide bracket.

18.Install the radiator upper hose.

Tighten the radiator hose clip.

Tightening torque:5 N.m(0.5kg-m/43 lb-in)

19.Refill the coolant.