This instruction show you guide on how to diagnose rough running or stalling for Detroit Diesel Gen5 DD platform engine.

Preparations:

2024 Detroit Diesel Diagnostic Link DDDL 8.19 8.09 Free Download

Procedures:

1.Connect DiagnosticLink .

2.Turn ignition ON (key ON, engine OFF).

3.Are any of the following fault codes present?

SPN 1077/FMI 7 Rail Pressure Deviation

SPN 157/FMI 16 Rail Pressure Deviation

SPN 3250/FMI 0 DOC Outlet Temperature Very High

SPN 3246/FMI 0 DFP Outlet Temperature Very High

3a Yes; perform the troubleshooting for the fault code.

3b No; Go to step 4.

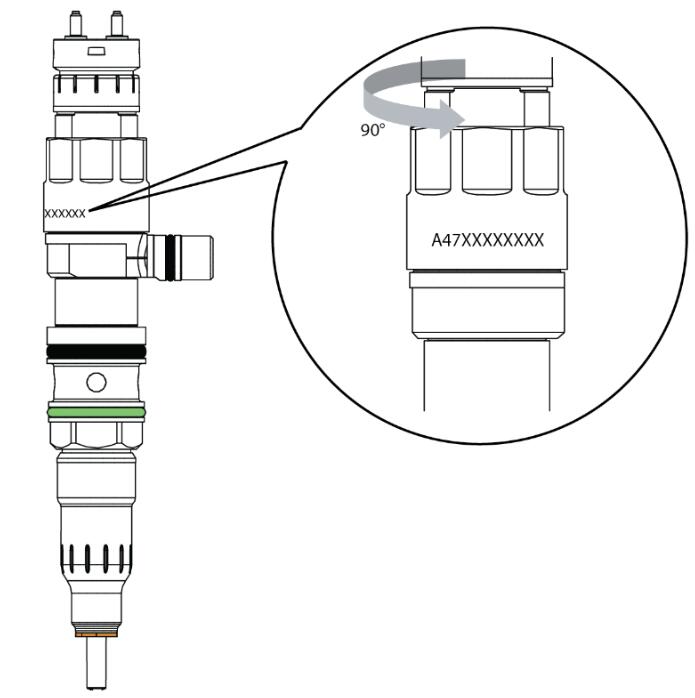

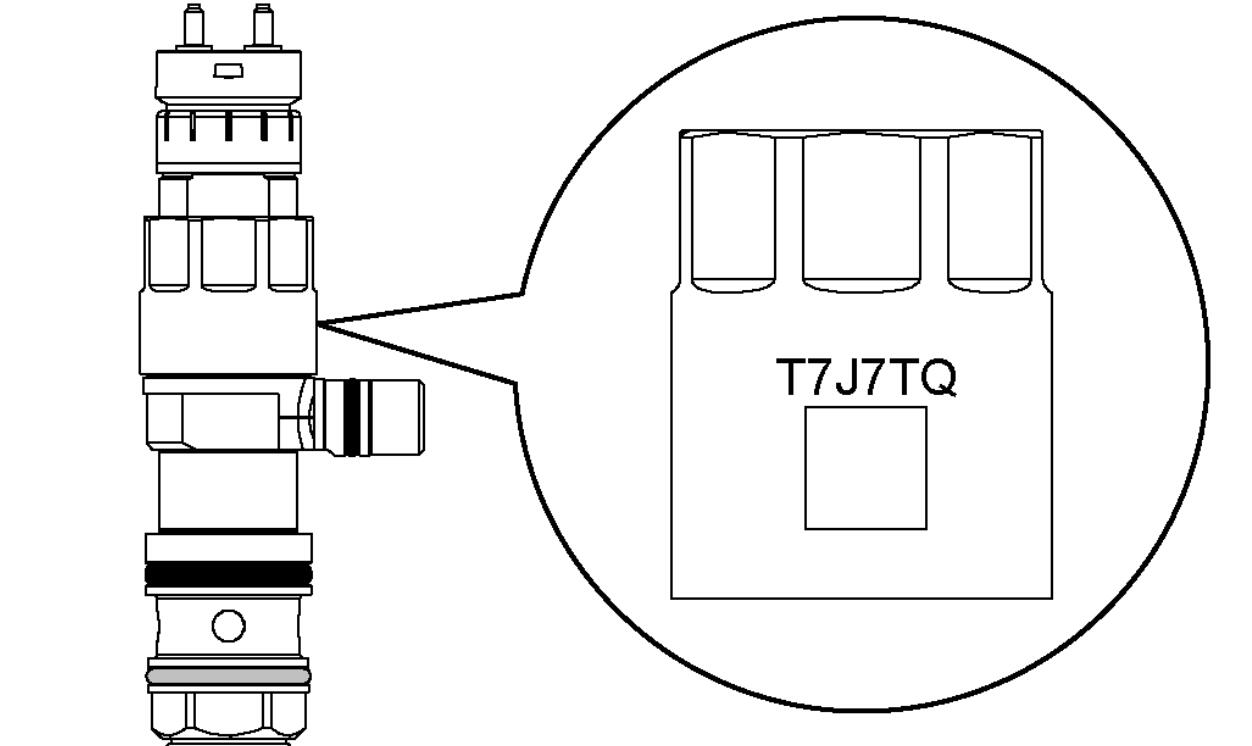

4.Using DiagnosticLink, Key ON, Engine OFF (KOEO), monitor the EGR delta P voltage with the coolant temperature above 65°C (150°F). Is the EGR Delta P voltage between 0.55 to 0.82 volts?

4a Yes; Go to step 5.

4b No; perform the troubleshooting for SPN411/FMI 13.

WARNING

PERSONAL INJURY

Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm.

Always start and operate an engine in a well ventilated area.

If operating an engine in an enclosed area, vent the exhaust to the outside.

Do not modify or tamper with the exhaust system or emission control system.

WARNING

ENGINE EXHAUST

To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area. Engine exhaust is toxic.

WARNING

PERSONAL INJURY

To avoid injury before starting and running the engine, ensure the vehicle is parked on a level surface, parking brake is set, and the wheels are blocked.

5.Disconnect the delta P electrical sensor. Key ON Engine Running, idle the engine for 30 seconds, then using the accelerator pedal, increase the engine to 1000 rpm. Did the engine stop surging?

5a Yes; clean the Exhaust Gas Recirculation Venturi ports and verify repairs.

5b No; Go to step 6.

Note : If the fuel mass is over 50 mg/st at 600 rpm (engine at operating temperature), abort the FSIC routine and Go to step 7.

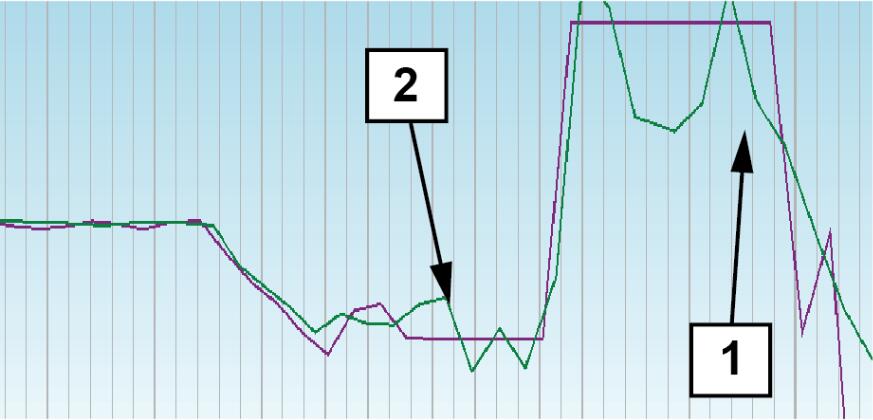

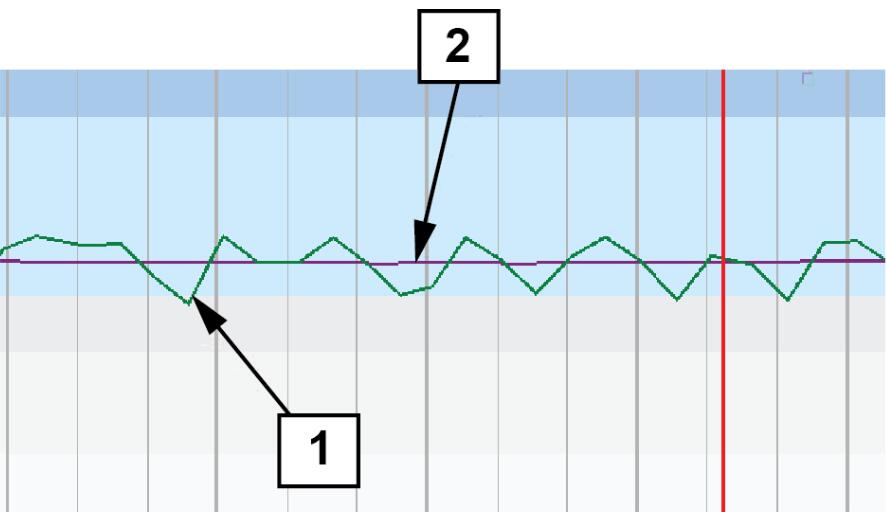

Note:See examples of erratic pressure showing (1) ASL001 Rail pressure and (2) AS098 Desired rail pressure.

6.Run an automatic Fuel System Integrity Check (FSIC) test. Review the automatic FSIC log file. Does ASL001 Rail Pressure have a saw tooth pattern or does the desired rail pressure and rail pressure deviate by more than 50 bar (725 psi)?

6a Yes; replace the Quantity Control Valve (QCV).

6b No; Go to step 7.

7.Review the automatic FSIC log file. At 600 rpm, is fuel mass over 50 mg/st?

7a Yes; replace both engine brake solenoids.

7b No; Go to step 8.

8.Check for aerated fuel. Refer to section “Aerated Fuel Test ” . Is fuel aerated?

8a Yes; if fuel is aerated, repair or replace as necessary.

8b No; if fuel is not aerated, Go to step 9.

9.Check for loose connections, kinked fuel lines or issues related to the fuel system. Were any issues found with the fuel system?

9a Yes; repair or replace as necessary.

9b No; Go to step 10.

Note : If rust is found in the filters, Refer to section “Diesel Exhaust Fluid in Fuel” .

10.Remove the Fuel Prefilter and Fuel Coalescer/Final Filter. Check for damaged or missing seals at the bottom of filters. Are damaged or missing seals at the bottom of the filters?

For Gen 5 DD13 and DD15 engines: Refer to section “Removal of the Fuel Prefilter” and Refer to section “Removal of the Coalescer/Final Filter” .

10a Yes; replace fuel filters as necessary.

10b No; Go to step 11.

11.Check air vents at the top of the Fuel Coalescer/Final filter for blockage. Is any blockage found?

11a Yes; replace the fuel filter as needed.

For Gen 5 DD13 engines: Refer to section “Installation of the Coalescer/Final Filter” .

For Gen 5 DD15 engines: Refer to section “Installation of the Coalescer/Final Filter” .

11b No; Go to step 12.

Note : Use the appropriate parts catalog to verify injector part numbers.

12.Verify the fuel injector(s) part number is correct for engine application. Is the fuel injector(s) part number correct?

12a Yes; Go to step 13.

12b No; install correct fuel injector(s).

13.Compare calibration code(s) using the DiagnosticLink panel “Injector Codes” with six-digit calibration code(s) on the fuel injector(s). Do the calibration codes match the appropriate cylinder?

13a Yes; Go to step 14.

13b No; correct the calibration codes using DiagnosticLink.

14.Check valve lash and engine brake rocker lash. Is valve lash within specification?

14a Yes; Go to step 15.

14b No; readjust lash and retest.

15.Using DiagnosticLink®, perform a relative compression test; Refer to section “Relative Cylinder Compression Test” . Are the results in range?

15a Yes;replace all six fuel injectors.

For Gen 5 DD13 engines: Refer to section “Removal of the Fuel Injector” .

For Gen 5 DD15 engines: Refer to section “Removal of the Fuel Injector” .

15b No; perform a Mechanical Cylinder Compression Test. Refer to section “Mechanical Cylinder Compression Test” .

For more repair case about Detroit,please refer to:Detroit Diesel Engine Repair