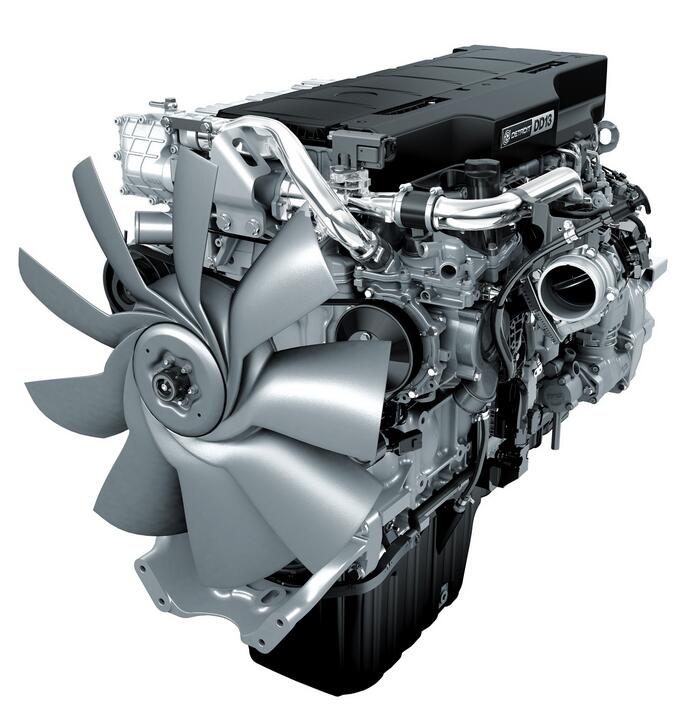

Detroit GHG17 Heavy Duty Engine Power Verification With Chassis Dynamometer.

The chassis dynamometer is a device for applying specific loads to a vehicle to determine if the vehicle will perform to published specifications and to permit a physical inspection for leaks of any kind. It can be used for detecting improper tune-up, misfiring fuel injectors, low compression, and other malfunctions.

Related Contents:

2024.06 Detroit Diesel Diagnostic Link DDDL 8.20 8.09 Free Download

Chassis Dynamometer Room Ventilation Recommendations

For safe and accurate dynamometer readings, the chassis dynamometer room must be properly ventilated.

If a vehicle is tested on a dynamometer located in an area without proper ventilation, the engine will be subject to high ambient air temperatures. High air inlet temperatures can result in false low power readings on the dynamometer.

To help ensure accurate horsepower readings, the dynamometer room should have a ceiling-mounted fan with an 850 to 1133 m³ /min (30,000 to 40,000 ft³ /min) capacity. This will provide proper ventilation of exhaust gases and heat radiated by the operating engine.

Chassis Dynamometer Test and Run-in Procedure

The function of the dynamometer is to absorb and measure the engine output after it has been transmitted through the vehicle transmission and driveline to the drive tires.

The vehicle is connected to the dynamometer through the roller absorption unit. The load on the vehicle may be varied from zero to maximum by decreasing or increasing the resistance in the unit. The amount of power absorbed in a water brake-type dynamometer, as an example, is governed by the volume of fluid within the working system. The fluid offers resistance to a rotating motion. By controlling the volume of water in the absorption unit, the load may be increased or decreased as required.

Refer to section “Minimum Acceptable Wheel Horsepower”

- Follow all applicable safety procedures from the chassis dynamometer manufacturer.

- Observe the air intake duct and charge air fan shrouding to identify misalignments. Correct as necessary.

- Make sure the differential lock is ON.

- Make sure the radiator/charge air cooler system fan(s) are locked ON.

- If the vehicle is equipped with anti-lock brakes (ABS), disable the ABS controller by unplugging it or removing its power fuse/breaker.

- Instrument the engine for fuel pressure, air inlet restriction, exhaust backpressure, and crankcase pressure, and note these readings during the dynamometer run.

- Make sure the vehicle hood is down and locked into its normal position.

- Make sure the engine is fully warmed up before placing the vehicle on the dynamometer. Both oil and coolant temperature should be at least 82°C (180°F).

- When loading the vehicle on the dynamometer, make sure the vehicle is positioned onto the rollers as straight as possible.

- For direct engine cooling, Detroit™ recommends the use of a 368 m³/min (13,000 ft³/min) or greater capacity barrel-type ram air fan. This should be portable so that it can be conveniently placed three to five feet (approximately one to two meters) in front of the truck and aimed directly at the charge air cooler. This is especially important at high altitudes.

- During high ambient temperature conditions 32°C (90°F), it may also be necessary to use a water spray mist fan in front of the vehicle to prevent overheating.

- Running the dynamometer in manual mode instead of automatic mode allows for maximum control of the test process and may result in more consistent test results.

- During the horsepower test, make sure percent engine load and torque limiting factor are 100% by monitoring them with a computer equipped with DiagnosticLink.

- Select a transmission gear with a 1:1 gear ratio during the horsepower test.

- Take horsepower reading at peak torque and peak horse power rpm. Stabilize at rated speed for at least one minute before taking a final horsepower reading. Compare the recorded horsepower to the appropriate minimum horsepower table for the particular rating.

- Note that “Minimum Acceptable Wheel Horse Power” information is for vehicles with manual transmissions. Vehicles with automatic transmissions (i.e. equipped with torque converters) will have slightly lower minimum horsepower values than those listed.

More repair cases for Detroit Diesel engines,please refer to:Detroit Diesel Engine Repair