This instruction show you guide on how to solve Doosan excavator P0408 maximum EGR rate governor deviation error.

Preparations:

Doosan Data Monitoring System DMS-5 DMS-3 Free Download

2023 Doosan Diagnostic Tool DDT & G2 Scan Software Free Download

1 Overview

“E” SPN FMI:E00323616

REASON:

1 Air path problem (EGR cooler plugged, Tampering by user)

2 Air path problem (EGR path leakage, Intake air path leakage)

3 Electrical problem (Faulty Air mass flow sensor, Faulty Intake manifold pressure sensor)

EFFECT:

CE lamp ON Torque Reduction 1(Mild) Inducement Group1 (EGR Block) – with EGR

Only DPF regeneration inhibit by Active and Forced

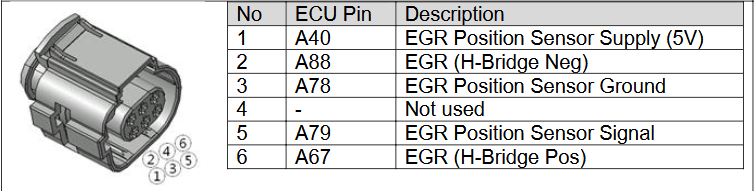

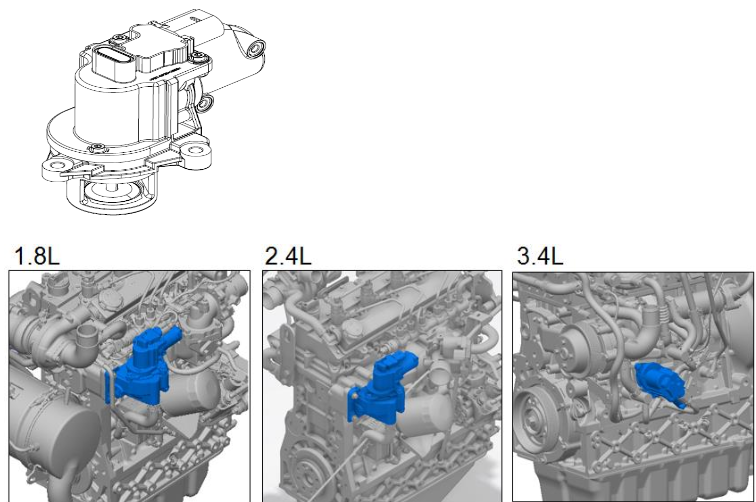

2 Component Location

3) Condition for Running Diagnostic

During engine running, Coolant temperature > 60 degC

4) Condition for Setting the Fault Code

The limit for the maximum permissible positive closed−loop EGR rate control deviation of the

exhaust gas recirculation control has been exceeded.over than 60sec.

5) Condition for Clearing the Fault Code

The limit for the maximum permissible positive closed−loop EGR rate control deviation of the

exhaust gas recirculation control has been within operation range.

The fault is healed only after key off & on condition.

6 Check List

6) Check List

| Step | Inspection | Standard

Value |

YES | NO |

| 1 | P0408 is detected on service tool? | Step2 | ||

| 2 | Let the machine be in safety area, and key OFF. | Step3 | ||

|

3 |

Check the EGR pipe between exhaust manifold and EGR valve?

Is there any leakage? Or blocked line ? If no leakage is found visually, Start up the engine and check the leakage/blocked again in machine stationary condition. |

Step7 |

Step4 |

|

|

4 |

Check EGR pipe between EGR cooler and intake manifold.

Is there any leakage? Or Blocked line ? If no leakage is found visually, Start up the engine and check the leakage/blocked again in machine stationary condition. |

Step7 |

Step5 |

|

|

5 |

Check intake air path between Air filter and intake manifold.

Is there any leakage? If no leakage is found visually, Start up the engine and check the leakage again in machine stationary condition. |

Step7 |

Step6 |

|

|

6 |

Is there any fault code related intake manifold pressure sensor, intake manifold temperature sensor?

If yes, fix the fault based on its troubleshooting guide. |

Fix the fault

based on its troubleshooti ng guide |

Step8 |

|

|

7 |

Fix the leakage/blocked line or change the pipe.

After fix, start the engine and change the RPM from low idle to high idle. Keep the RPM as high idle at least 60 seconds. Fault code is cleared? |

Problem solved |

Step8 |

|

|

8 |

Is there abnormal value of intake manifold pressure sensor or air mass flow sensor? (ex. Service tool value is not increase even engine speed increase)

*Variables 1) Engine speed(Epm_nEng) 2) Intake manifold pressure (Air_pIntkVUs) 3) Air mass flow (AFS_dmSens) 4) Model air mass flow (AirMod_mfGasIntkVlv_f) |

Step 9 |

Contact Helpdesk |

|

|

9 |

Change the suspected parts, start the engine and change the RPM from low idle to high idle.

Keep the RPM as high idle at least 30 seconds. Fault code is cleared? |

Problem

solved |

Contact

Helpdesk |

More topics for Doosan,please refer to:Doosan Trouble Repair