In this instruction,we’ll show you how to easily fix a o6 inch bumper crack by using plastic welding.

Related articles link here for further reference:

How to Repair Torn TPO Bumper with Rods

How to DIY Repair Big Crack on Bumper for Nissan

The tools we need:

180 grit Sander

Aluminum tape

Basic glass cleaner

Dremel with a teardrop bit

Procedures:

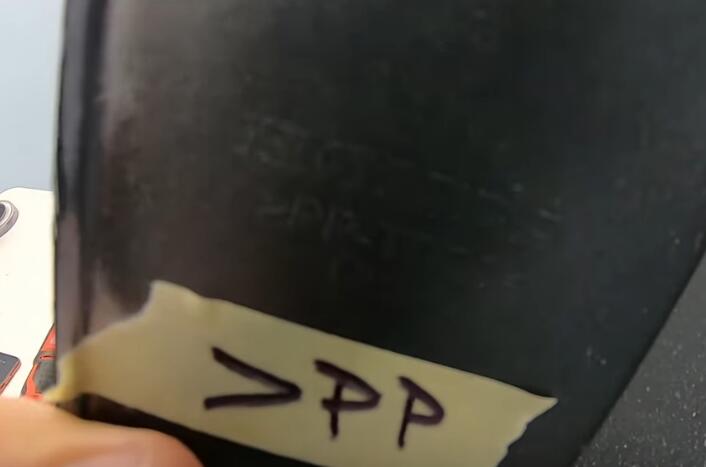

Before we start anything, identify plastic first. In our case, it marks “Honda PP”(Polypropylene)

So that we’ll go ahead and find polypropylene

Use aluminum tape to hold the crack on front side

Use glass cleaner or wax and grease remover to clean the crack surface backside to make sure it doesn’t have any silicone or anything of that nature.

Use 180 grit sander to get some overspray from underside the bumper

Blow it off

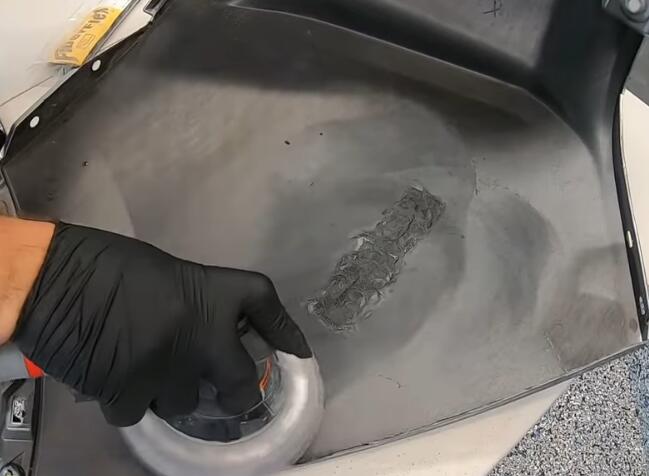

Put a half inch all around the crack with mesh to reinforce the back area

Melt mesh into the bumper, weld it very gentle, then smooth welds out

Use 180 grits sander to take the glossiness away

Get a little bit beat up to melt the rod one side first, then put it on the crack, break it off, melt rod in, pressed appropriately down into all those little grooves

After do that, back side is finished.

Sander front side crack with 180 grit.

Use the teardrop shaped dremel attachment to make a v-groove crack

Feed polypropylene rod into welder slowly

Weld fiber flex rod on the low spot where the groove we just made

Use 180grits sander smooth it out. After do that, we’ll find some little divots there.

Use a poly-flex flexible polyester or glazing putty to fill in those little divots.

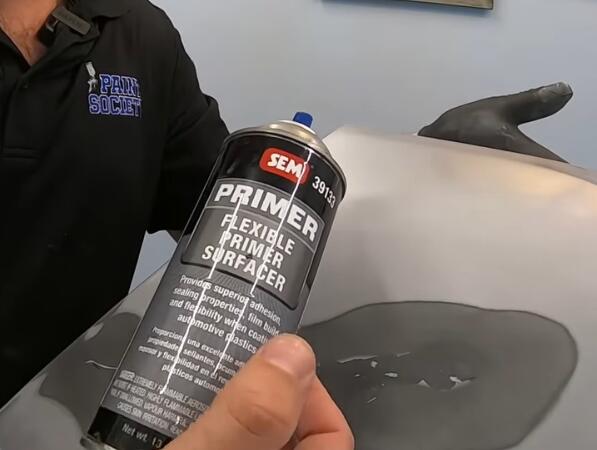

Use 180 grits sander smooth it out again then use some flexible primer on it

More cases about crack replacement, please refer to CRACK REPAIR.