This instruction show you guide on how to install gearmotor for JLG X14J Lift machine.If you want more information for JLG machine,please refer to:JLG Technical Library Service Repair+Parts Manual 2020 Download

Before proceeding with installation, follow the instructions given below.

1.Properly clean the product by removing packaging and all remains of protection padding.

2.Prepare the parts to be coupled using the installation drawing as a guide.

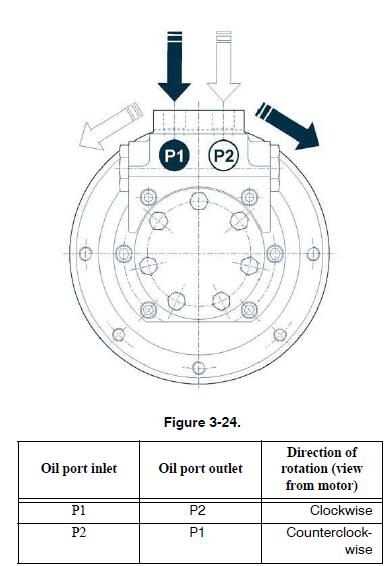

When assembling the track drive on the machine and connecting the hoses, follow instructions shown in below sketch for proper direction of rotation.

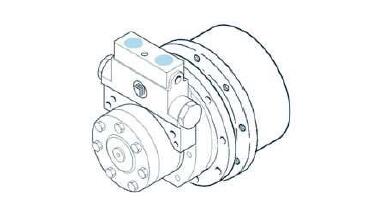

MOUNTING THE PRODUCT TO THE MACHINE

3.Move the gearmotor in the mounting area applying lifting methods.

4.Install the motor gearbox connecting it to the machine frame and to the sprocket using all screws as the thread holes on to the flanges. Lock the screws with the tightening torque shown in the following scheme.

CONNECTIONS TO THE HYDRAULIC SYSTEM

5.Make sure that the entire hydraulic system meets the cleaning standard as given in level 9 according NAS 1638 or 18/15 ISO/DIS 4406.

6.Clean the surface to be connected on the hydraulic motor.

INFORMATION

ONLY WHEN IT IS NECESSARY TO ATTACH PIPES,REMOVE THE PLASTIC CAPS PROTECTING THE

CONNECTIONS, THIS WILL ENSURE THAT NO FOREIGN BODY GOES INSIDE THE HYDRAULIC MOTOR.

7.Pipe the hydraulic motor as shown below (for pipe sizes and dimensions refer to the installation drawing).

Main ports: P1-P2

FILLING-UP THE GEARBOX WITH LUBRICATING OIL

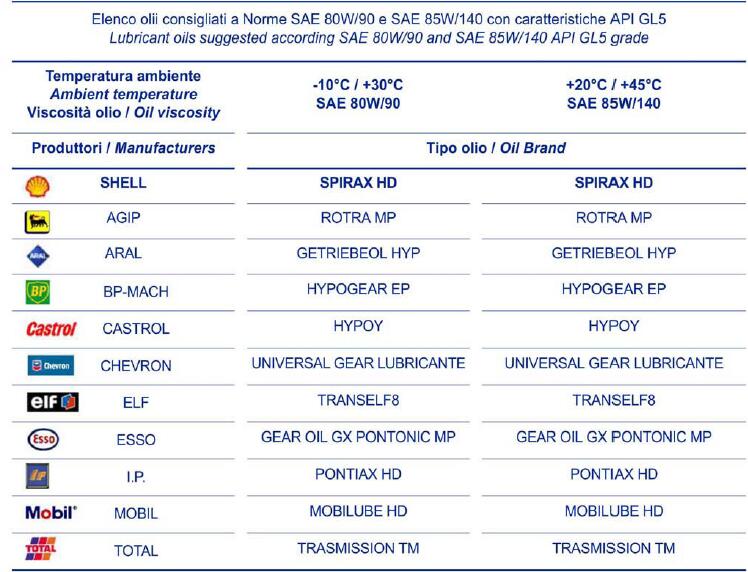

Before starting up the motor gearbox, check the level of lubricating oil in the gearbox. Check that the gearbox axis is horizontal. If necessary, refill with lubricant oil.

This procedure is undertaken following the indications given below.

INFORMATION

DO NOT MIX TOGETHER OILS OF DIFFERENT BRANDS OR CHARACTERISTICS.

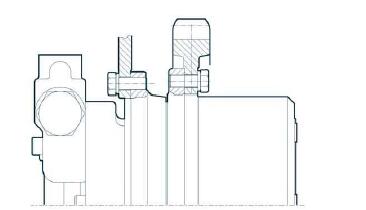

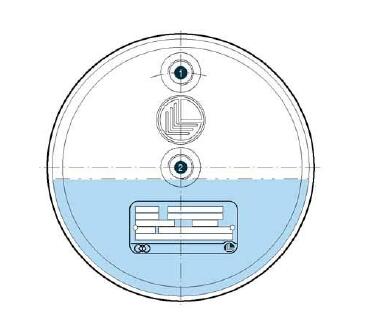

8.Rotate the gearbox housing, so that the plug (1) is on the top of the cover.

9.Unscrew the two plugs (1-2) and fill from the upper hole until the oil flows out from the hole (2).

10.Tighten the oil plugs (1-2) and let the gearbox run.

After a few minutes, stop and check the oil level.If necessary, refill.

Approximate oil capacity = 0,5 liters ±10%

CHARACTERISTICS OF THE HYDRAULIC SYSTEM

The oil in the hydraulic system (which also lubricates the hydraulic motor) must reflect the ISO VG 46 characteristics.

It must be filtered with a maximum grade of 10μm and with a level of contamination equal to or inferior to class 9 according to NAS 1638 or 18/15 as stated in ISO/DIS 4406.

It is advised not to mix together oils with different properties.

It is advised to use a filter with a led indicator that can be seen externally, with a flow control valve that blocks the flow of oil when the filter is clogged.

If it is necessary to work in low temperatures (artic climates) it is essential to use specific guidelines (contact the manufacturer).

Checking the temperature of the hydraulic oil is one of the most critical aspects of the hydraulic system.

High operational temperatures will cause a degradation of the oxidation resistance level and will accelerate the deterioration process of the hydraulic oil.

Therefore fl is important to follow the measures below.

– The temperature of the hydraulic oil during working conditions should remain between 30°C and 60°C.

-The temperature of oil should reach 20°C prior to start operation.

-During operation the oil temperature can rise to 90°C but this temperature is acceptable only for very short periods of time.

These temperatures have been set to take into consideration general degrading in viscosity as well as the wear respiting additives used in the oil.

The life of the motor will be shortened considerably if the operating temperature is constantly at a level that is hash er than 60°C.

FIRST START UP AND RUNNING IN

In this first stage it is advised to follow the measures given below.

11.Bleed air from every part of the hydraulic circuit and add oil in the tank if necessary.

INFORMATION

THE PRESENCE OF RESIDUAL AIR IN THE HYDRAULIC CIRCUIT WILL MANIFEST ITSELF WITH THE

PRESENCE OF FOAM IN THE TANK AND WILL LEAD TO A JERKING OF THE MOTOR AS WELL AS EXCESSIVE NOISE COMING FROM THE MOTOR AND THE VALVES.

12.Start the gearmotor at a low speed and gradually increase it after having verified that it is functioning correctly without any noises or vibrations.

INFORMATION

DO NOT REACH MAXIMUM PRESSURE UNLESS THE ENTIRE SYSTEM HAS BEEN FILTERED TO ELIMINATE ANY PARTICLES OF DIRT THAT MAY BE PRESENT.

During the running-in stage follow the steps given below.

13.Make sure that the speed and direction of rotation are correct.

14.Make sure that the functioning is regular and without any excessive noises and vibrations.

15.Make sure that the oil temperature does not exceed 60°C.

After having terminated this first running-in, follow the steps given below.

16.Check that there are no oil leakages. If present, proceed to remove them.

17.Check that there are no other problems in general.

More case for JLG Lift,please check:JLG Lift Trouble Repair