This instruction show you guide on how to remove,install and inspect cylinder head for Linde HT30D forklift truck.

Preparations:

2023 Linde Service Guide LSG 5.2.2 U0278 and 5.1.2 Free Download

Procedures:

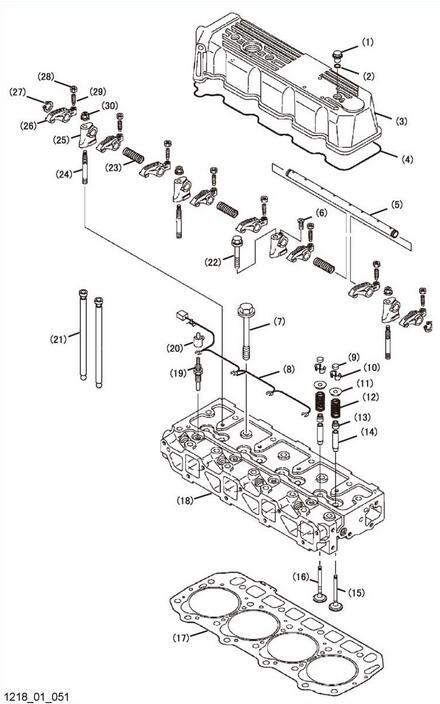

Cylinder Head Components

1 Valve cover nut

2 Valve cover nut O – ring

3 Valve cover

4 Valve cover gasket

5 Rocker arm shaft

6 Rocker arm shaft retaining screw

7 Cylinder head bolt

8 Glow plug harness

9 Valve cap

10 Valve keepers

11 Spring retainer

12 Valve spring

13 Valve stem seal

14 Valve guide

15 Intake valve

16 Exhaust valve

17 Cylinder head gasket

18 Cylinder head

19 Glow plug

20 Glow plug cover

21 Push rod

22 Support bracket bolt

23 Rocker arm shaft spring

24 Support bracket stud

25 Support bracket

26 Rocker arm

27 Rocker arm shaft retaining ring

28 Valve adjusting screw lock nut

29 Valve adjusting screw

30 Support bracket nut

Removal of cylinder head

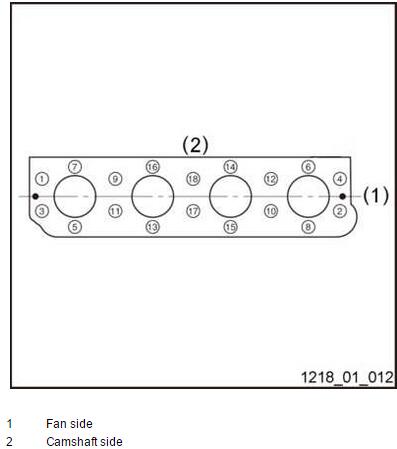

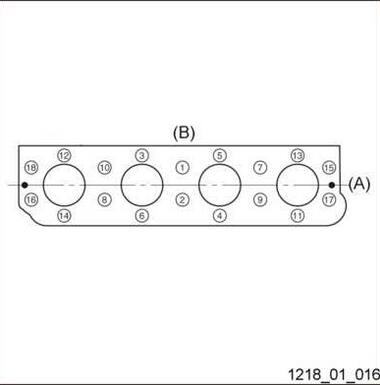

➢Loosen the cylinder head bolts following the sequence shown.

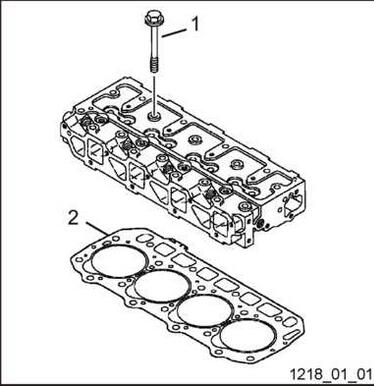

➢Remove the cylinder head bolts (1)

Lift the cylinder head away from the cylinder block. Discard the cylinder head gasket (2) .Position the cylinder head on the work bench to prevent damage to the combustion surface.

Assembly of cylinder head

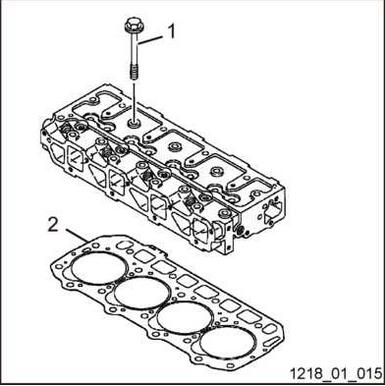

Carefully clean both the combustion surface of the cylinder head and the top surface of the cylinder block.Then place a new cylinder head gasket (2) on the cylinder block.

Position the cylinder head on the cylinder head gasket.

➢Lightly oil the threads of the cylinder head bolts (1) .Torque the bolts in steps to the specified torque in table following the sequence.

A: Fan side

B: Camshaft side

First Step 49-58.8 N.m

Second Step 103.1-112.9 N.m

➢Insert the push rods in their respective positions.

Inspection of cylinder head

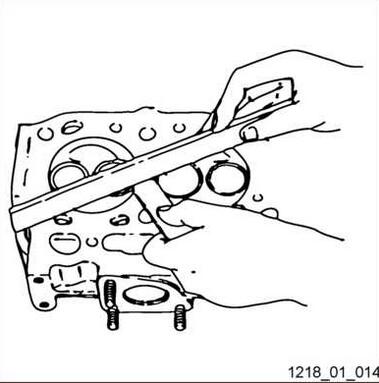

Cylinder head distortion

Place the cylinder head flat and inverted (combustion side up) on the bench . Use a straight edge and feeler gauge to measure the amount of cylinder head distortion .

Inspection Item Standard Limit

Combustion surface distortion (Flatness) 0.05mm or less 0.15 mm