On previous article, we instruct How to Repair Broken Straight Flange Slot Tabs on Bumper Cover, now we’ll repair a slot tab where the flange follows the curvature of the slot.

Procedures:

Cut out the bar

Here, we’ll use the round rod since it can make curves a lot easier than the ribbon can.

Use a V-groove into the plastic deeply with a sharp carbide burr like our part number 6125 ,

Make a deep v-groove right to the edge of the slot, that gives us strength across the gap

Remove the burrs and also remove the paint from the edges of the flange

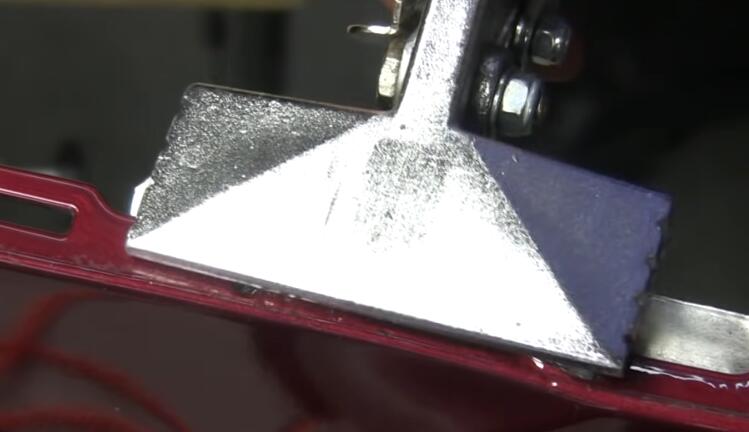

Using aluminum tape stick on back side to make the foundation stiffer

Pre-heat the bumper and the end of the polypropylene rod, direct more heat onto the rod, since the bumper is so thin.

Note that the angle of the torch to the bumper is almost flat.

Pick it up on the other side and continue to weld all the way to the end.

Reheat the rod until it turns translucent, then lightly squeeze with the hand seamer tool to get the repair to the same thickness as the flange.

Peel off the aluminum tape and then use the hot welder tip, a razor knife and a rotary tool as required to reshape the slot and the flange

DA the plastic to get it to the final shape