This instruction show you guide on how to perform hydraulic system test for Linde C357-05 C4026 forklift trucks.

Related Contents:

Linde Truck Doctor 2.01.05 Forklift Truck Diagnostic Free Download

2023 Linde Service Guide LSG 5.2.2 U0278 and 5.1.2 Free Download

Linde Pathfinder Diagnostic v3.6.2.11 2020 2019 Software Free Download

➢ Check the hoses, pipes and connections for leaks and check that they are securely fitted.

➢ Visually check for leakages.

➢ Check the oil level in the hydraulic tank.

NOTE

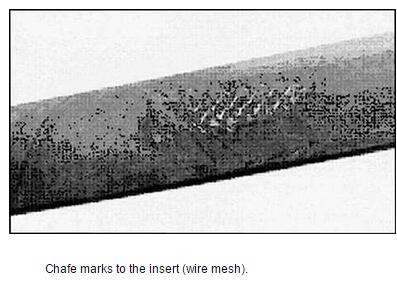

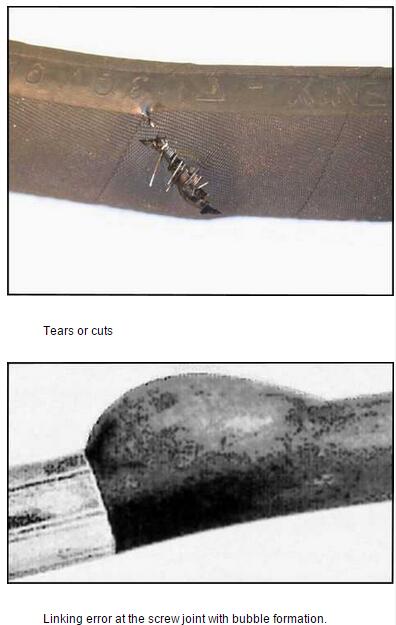

Hydraulic hoses become brittle over time!

Hydraulic hoses must not be used for a period of longer than six years.

The BGR 237 specifications must be complied with.

Differing national laws must be taken into account.

Hand pallet truck hydraulics lifting system

➢ Test the function of the hydraulic overload valve.

➢ Test the hydraulic pump for leaks.

Tilt cylinder

Checking for internal leaks

➢ Pick up the highest available load or the maximum nominal load and lift to a height of approximately 2.5 m.

➢ Set lift mast to vertical. Check this position with the tilt spirit level.

➢ After 10 minutes check the position of the lift mast. Determine tilt angle. The lift mast may tilt forwards by itself up to a maximum of 5° within 10 minutes.

Lift cylinder

NOTE

Bring hydraulic oil up to operating temperature (approx. 20-40°C).

Checking for internal leaks

➢ Set lift mast to vertical.

➢ Pick up the load and lift it approximately 1 m.

➢ Measure this position accurately with the metre rule.

➢ After 10 minutes, check this position again. The nominal load must not lower by more than 100 mm within 10 minutes.

NOTE

On an industrial truck with a load-bearing capacity of more than 10 t, the nominal load may lower by a maximum of 200 mm within 10 minutes.

More service information,please refer to:Linde Forklift Truck Repair