This instruction show you guide on how to do insulation testing for Still RX20 forklift electric trucks.More topics about Still trucks,please refer to:Still Forklift Repair

Related Contents:(all workshop manual included in below software)

STILL STEDS Forklift 8.19 8.18 2019 EPC & Diagnostics Free Download

Insulation testing must be carried out on the entire truck at least once a year as part of the FEM test.Insulation testing must also be carried out after any work on the electrical system or repairs to the electrical system.

Insufficient insulation values in the truck can lead to undefined errors that are not reliably detected in the diagnostic process.

This test measures the insulation of the entire truck.

If insufficient measured values are obtained, the insulation must be measured for the following components to ensure that no errors are present:

• Traction motor

• Pump motor

• Battery

Dangerously high voltages may be present in the electrical drive system (converter, traction motor,pump motor)!

Always observe the safety information; refer to the chapter entitled “Safety information”.

Before working on the converter, the charging state of the intermediate circuit voltage must always be checked first.

– If the intermediate circuit voltage does not automatically discharge to 0 V, the intermediate circuit must be discharged.

Measuring equipment

• STILL multimeter measuring device with measurement wires

• Short-circuit bridge for the battery male connector on the truck

• Adaptor box for discharging the intermediate circuit and measuring the insulation. See the chapter entitled “Special tools” Preparing

– Park the truck securely.

– Disconnect the battery male connector.

– Connect the short-circuit bridge to the battery male connector on the truck.

–Measure the voltage of the intermediate circuit and discharge the intermediate circuit if necessary. See the chapter entitled “Intermediate circuit”.

– Unlock the emergency off switch, if fitted.

– Turn the key switch to ON.

– Remove the cover sheet on the counterweight.

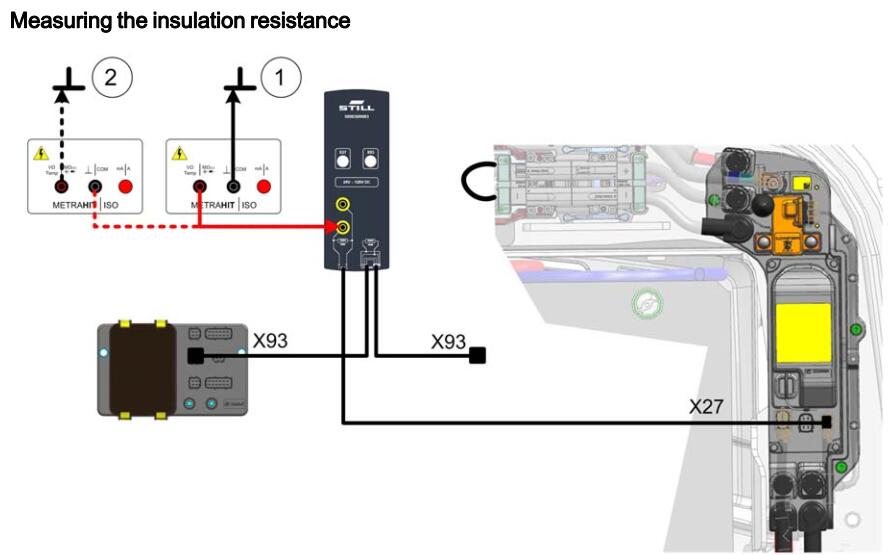

– Disconnect plug X27 on the PDU.

– Connect plug X27 on the adaptor box to plug X27 on the PDU.

– Disconnect plug X93 from the fuse box.

– Connect plug X93 on the adaptor box to the fuse box and to the wiring harness.

– Set the measuring device to the truck-specific test voltage.

– Insert the red measurement wire into the adapter box, X27 pin 1.

– Connect the black measurement wire to an area of bare metal on the truck chassis, e.g. the catch bolt on the door lock.

– Measurement (1): Insert both measurement wires into the measuring device.

– Hold down the ENTER button and read the value

NOTE

The measurement may take a few seconds,because capacities are transferred between the truck chassis and the electronics. The capacities produced during the measurement must be definitively discharged after the measurement.

– Release the ENTER button and wait until the voltage on the truck has dropped to 0 V.

The measurement must be carried out with both polarities, because many electronic components with direction-dependent breakdown characteristics are installed in the controllers.

– Measurement (2): Insert the measurement wires into the measuring device the other way

round.

– Hold down the ENTER button and read the value.

– Release the ENTER button and wait until the voltage on the truck has dropped to 0 V.

If the values deviate from one another, the lower value applies for the truck.

Follow-up work

– Remove the adaptor box and reconnect plug X27 and plug X93.

– Remove the short-circuit bridge from the battery male connector on the truck.

– Fit the cover sheet on the counterweight.

Insulation testing on the drive battery

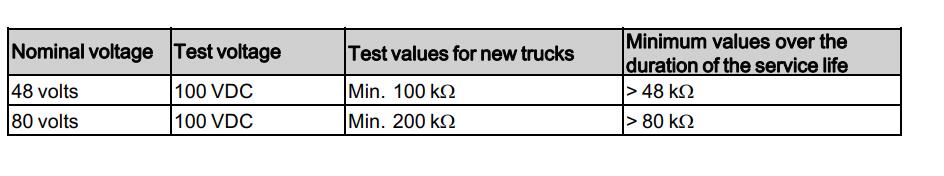

Extract from EN 1175-1, (UBatt < 120 V) Chapter 5.15.1, Test voltage:

• The insulation resistance of the truck and the battery must be tested individually.

• The test voltage must be greater than the nominal battery voltage but not higher than 100 V or three times the nominal battery voltage.

Chapter 5.15.1, Insulation resistance:

• The insulation resistance of the battery is tested when the battery is disconnected, filled and charged, and installed in the truck.

• The insulation resistance is tested between the electrically active parts of the battery and the battery tray.

• Test value [Ω] > (50 Ω/V x UBatt)

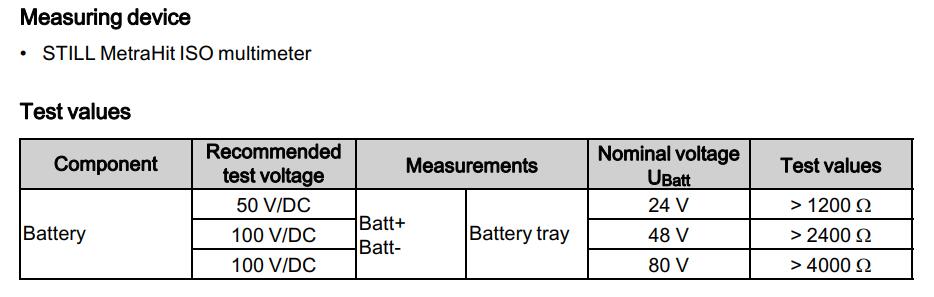

Performing battery measurements

– Disconnect the battery male connector.

– Set the measuring device to the truck-specific test voltage.

– Measure from the battery positive terminal against an electrically conductive point on the battery tray.

– Measure from the battery negative terminal against an electrically conductive point on the battery tray.

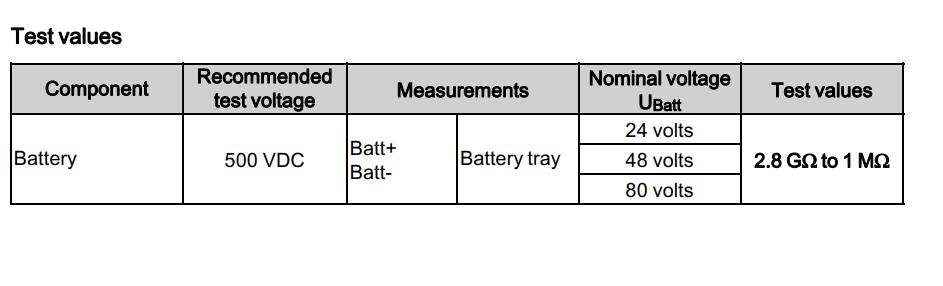

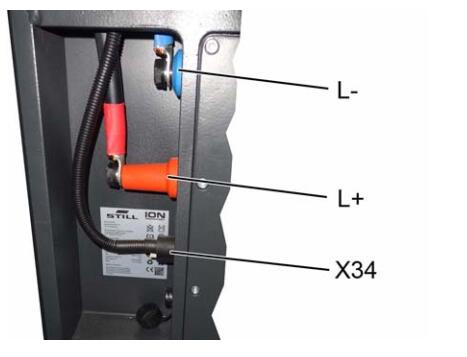

Insulation testing the lithium-ion battery

Performing battery measurements

– If the battery is still in the truck, disconnect the battery male connector.

– Set the measuring device to the recommended test voltage.

– Measure from the positive terminal (L+) of the battery to an electrically conductive point on the battery tray.

– Measure from the negative terminal (L-) of the battery to an electrically conductive point on the battery tray.

NOTE

The bare screws on the cover of the technology compartment are suitable conductive points.

DANGER

The insulation resistance measured is below 1 MΩ.

The battery is unsafe and must not be used again.

Switch off the battery. Contact the authorised service centre immediately.

Performing battery measurements

– If the battery is still in the truck, disconnect the battery male connector.

– Set the measuring device to the recommended test voltage.

– Measure from the positive terminal (L+) of the battery to an electrically conductive point on the battery tray.

– Measure from the negative terminal (L-) of the battery to an electrically conductive point on the battery tray.

NOTE

The bare screws on the cover of the technology compartment are suitable conductive points.

DANGER

The insulation resistance measured is below 1 MΩ.

The battery is unsafe and must not be used again.

Switch off the battery. Contact the authorised service centre immediately

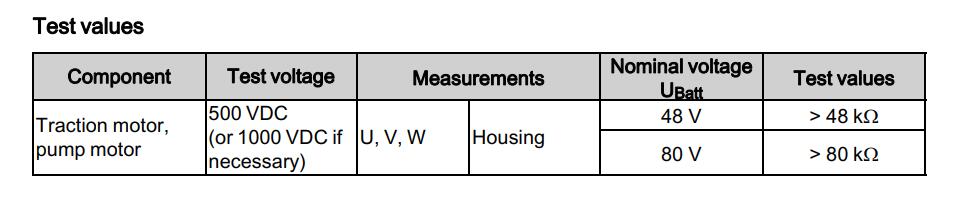

Component insulation testing

During insulation testing of the entire truck, if the insulation values measured were insufficient, it is a good idea to test the components of the traction motor and pump motor individually.

DANGER

Dangerously high voltages may be present in the electrical drive system (converter, traction motor,pump motor)!

Always observe the safety information; refer to the chapter entitled “Safety information”.

Before working on the converter, the charging state of the intermediate circuit voltage must always be checked first.

– If the intermediate circuit voltage does not discharge to 0 V, particular care must be taken when working on the converter.

– The correct work sequence must always be followed when removing the converter.

CAUTION

The test voltage can destroy electronic components.

Disconnect the electrical connections for all controllers.

Measuring equipment

• STILL MetraHit ISO multimeter measuring device

• Short-circuit bridge for the temperature sensors

Preparing

– Disconnect the battery male connector.

– Disconnect the converter from the power supply by disconnecting the power cables and the control cables.

– Disconnect the truck control unit from the power supply by disconnecting both plugs.

The connection cables and, if necessary, the CAN bus plug, must be disconnected from the components, depending on the equipment.

Measuring the electric motor

– Set the measuring device to the truck-specific test voltage.

– Measure the traction motor windings U, V, W in relation to the housing.

– Measure the pump motor windings U, V, W in relation to the housing.

The measurements must be carried out one after another for each winding.

In order to verify a frame fault on electric motors,it may be necessary to increase the test voltage

to 1000 V.

Follow-up work

– Connect the power cables and the control cables to the converters.

– Connect both plugs to the truck control unit.

The connection cables and, if necessary, the CAN bus plugs, must be connected to the components, depending on the equipment.

Still Steds Navigator Forklifts 8.19 R2 Download & Installation Service